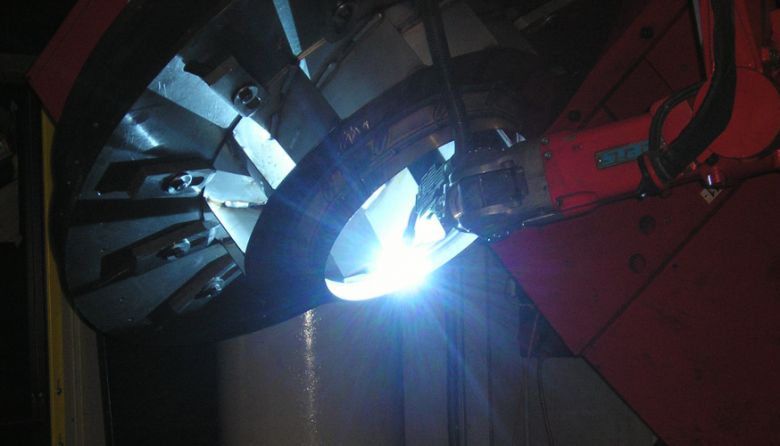

Metal Welding processes are still essential in many industries, where automotive industry is no exception. One of the later welding methods – namely laser welding – has been rapidly developing over the last years. Laser welding is more and more applied in the manufacturing of automotive components and body assembly (“body shop”). On components, as well as in bodywork, spatter free surface is essential. E.g. the “body in white” must got to the coating without any grinding or rework if the aim is to efficiently secure optimum quality. Grinding is non productive work and at the same time reduces the zinc layer, which potentially leads to reduced corrosion protection.

Hot metal spatter develops during spot welding/resistance welding, laser welding, MIG/MAG welding, MIG soldering, etc. If not protected, metal spatter burns into the sheet metal surface – in particular when welding zinc plated sheet metal. This reduces the quality in visible areas or in areas relevant to assembly and also negatively influences corrosion protection.

Metallotion PROTEC CE15L+ provides surface protection and maintains the surface quality, thus preventing reworking and allowing to go straight into following stages after welding works, be it MIG/MAG, laser welding or other methods.

The zinc layer is maintained and unproductive cleaning tasks become obsolete. Total process safety is guaranteed – from welding to cataphoresis/coating. The PROTEC fluid also equally protects during laser welding on aluminium sheets.

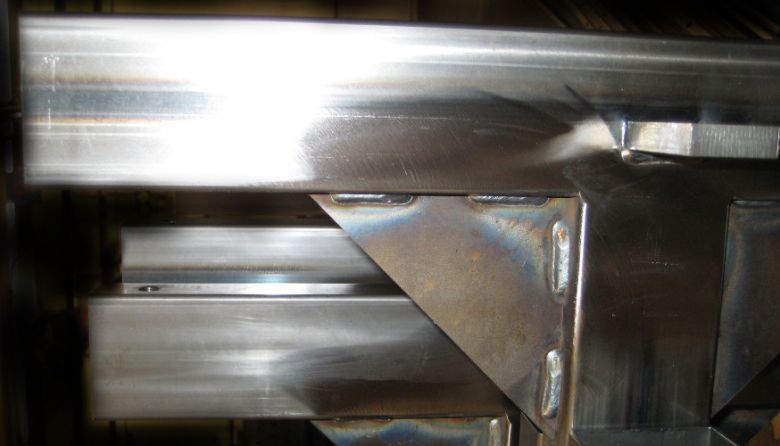

In car bodywork, PROTEC anti-spatter fluid mainly is used for protection of doors or body side parts/door entrances in laser welding processes or resistance welding processes.

The advantage of PROTEC anti-spatter fluids lies in its simple application and the strong protective qualities directly on the metal surface, even on complex structures.

The fluid is applied (up to three weeks) before welding. This is the only prerequisite to obtain reliable metal surface protection and other processes remain entirely unaffected. The PROTEC fluids can be applied manually or automatically. PROTEC team readily shares its professional expertise and offers consulting on effective and efficient application technology.