Requirements

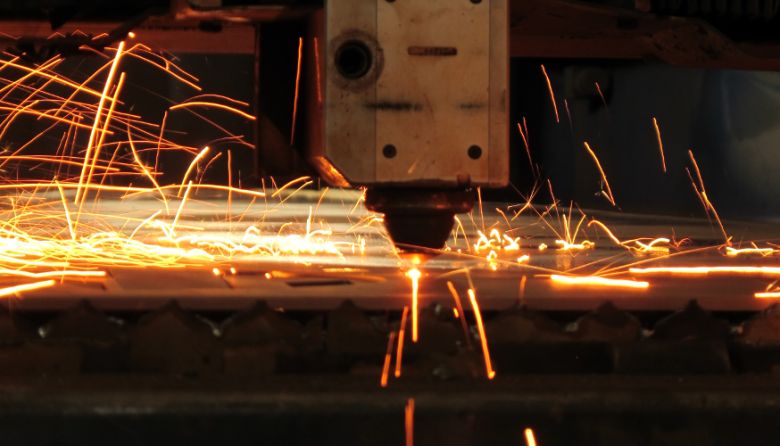

Slag and spatter develop during steel, aluminium, or stainless-steel laser cutting and thus causes significant contamination on workpieces and equipment.

Effective protection against adhering spatter and slag is required.

Process safety is vital – particularly for downstream processes, such as vibratory finishing, reforming, welding, etc.

Potential downstream coating must also provide ideal results.

Benefits

- Increased surface quality on cut parts

- More stable process when starting to move the beam after piercing

- Prevention of reworking on the workpiece and reduction of cleaning costs for supports

- For specialist cutters: offers a competitive edge with clean and dry laser-cut parts, ideally prepared for downstream processes

Application

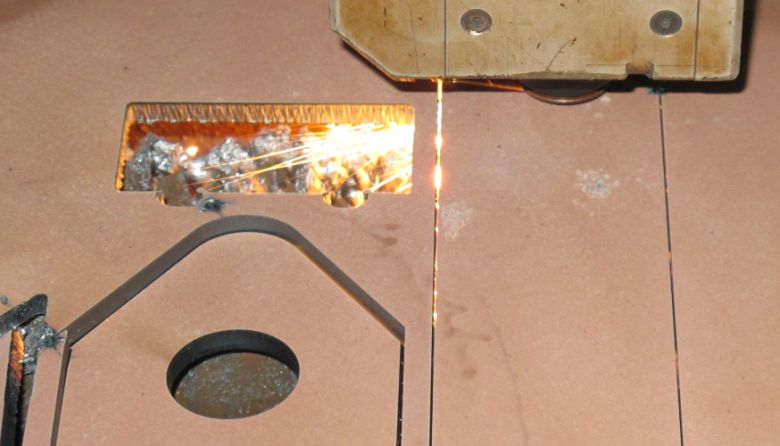

Spray the protection area (sheet metal, inside of pipes) using the Laser-Lotion PROTEC LC20A immediately before laser cutting process. A thin, sealed coat provides sufficient protection. Regularly spray supports on flatbed lasers.

PROTEC is suitable for all laser cutting processes including stainless steel laser cutting, steel, copper, aluminium laser cutting, etc.

Safety

PROTEC is safe and sustainable:

- Process safety also for downstream processes, such as welding and coating

- Safe for users and the environment: non-flammable, biodegradable

- Tested and approved, has been in use at renowned, international companies for many years