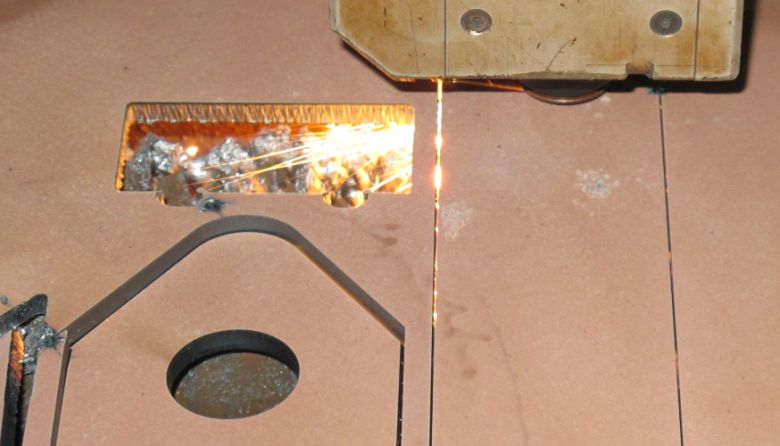

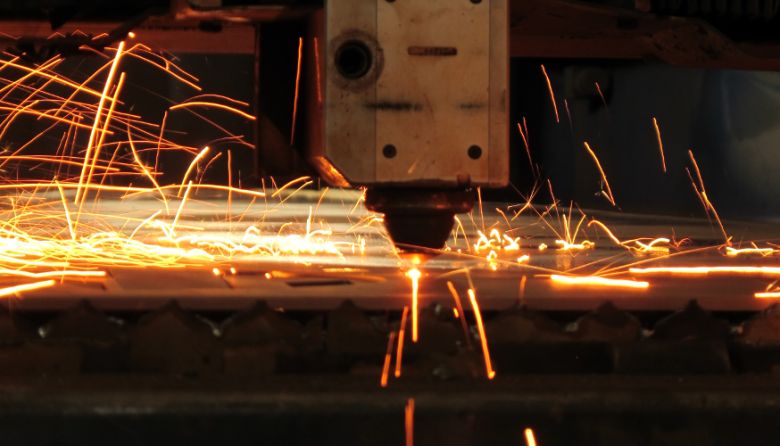

During laser cutting of sheet metal, spatter and slag adhere to the top side (when the beam penetrates the material) as well as the bottom side of sheet metal (reflection from below) and the supports.

Using Laser-Lotion PROTEC LC20A will effectively prevent adhering spatter and slag. This results in significant improvements, such as

- Increased process safety when starting to cut, as the ring of slag does not adhere to the penetration point.

- The surface quality of sheet metal is maintained – there is no need for reworking. For instance, when cutting stainless steel sheets particularly the bottom side of the sheet requires protection.

- Protecting the supports reduces any potential cleaning costs and increases the service life of the bars (also for copper bars).